Sodium carbonate (Na2CO3), often known as soda ash, is a necessary industrial chemical that is mostly utilized in the production of detergents and glass. Historically derived from plant ashes, its production shifted to the more efficient Solvay process in the 19th century.

Soda ash is used in many different sectors since it is essential for lowering the melting point of glass and softening water. This introduction provides a snapshot of its uses and historical significance, setting the stage for a deeper exploration of its production methods and applications.

Production Methods of Soda Ash

The Solvay process and natural deposit mining are the two primary processes used to manufacture soda ash, also known as sodium carbonate. Every technique has distinct qualities and uses that are suited to certain economic and environmental factors.

Solvay Process

The most used technique for producing synthetic soda ash is the Solvay process, which was created in the 1860s by Belgian scientist Ernest Solvay. It involves several key steps:

- Ammoniation of Brine: Salt (sodium chloride) and limestone (calcium carbonate) are used as raw materials. The brine solution is treated with ammonia to start the process.

- Carbonation: Sodium bicarbonate is precipitated out of the ammoniated brine by the bubbles of carbon dioxide.

- Calcination: Pure sodium carbonate is produced by heating (calcining) sodium bicarbonate, which releases carbon dioxide and water.

This process is favored for its efficiency and for the fact that it is less harmful to the environment compared to older methods like the Leblanc process. It also allows for the recycling of ammonia, making it more sustainable.

Mining Natural Deposits

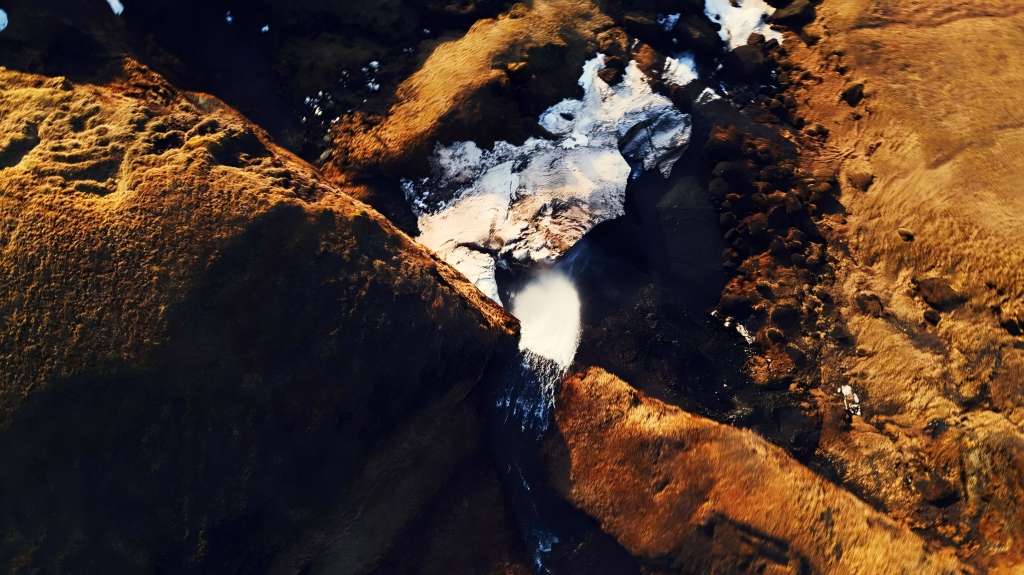

Another method for obtaining soda ash is through the mining of natural deposits of trona (hydrated sodium bicarbonate carbonate). This primarily occurs in regions like Wyoming, USA’s Green River Basin, which has the world’s largest known trona deposits. The process includes:

- Mining: Trona is extracted from the earth, typically through room-and-pillar mining.

- Processing: The mined trona is then processed, which involves crushing the ore and then heating it to convert it to pure soda ash.

Comparison and Uses

Each approach has benefits. The Solvay process is more widely used globally due to its ability to produce high-purity soda ash and its lower overall environmental impact. Mining is more region-specific and can be more cost-effective where natural deposits are abundant.

In conclusion, the manufacture of soda ash using these techniques supports a variety of commercial uses, such as the production of detergents and glass, underscoring its significance in international industrial practices.

Soda Ash’s Principal Industrial Applications

Sodium carbonate, sometimes known as soda ash, is a multipurpose industrial chemical that finds use in many different industries. Here are some of the key industries where soda ash is extensively used:

| Industry | Role of Soda Ash |

| Glass Manufacturing | Acts as a fluxing agent to lower the melting temperature. |

| Detergents & Cleaning | Used as a builder in detergents. |

| Chemical Production | Raw material for various chemicals. |

| Paper & Pulp | Utilized in the pulping process. |

| Water Treatment | Adjusts pH levels in water treatment. |

| Metallurgy | Employed in metal processing and smelting. |

| Industry | Role of Soda Ash |

| Glass Manufacturing | Acts as a fluxing agent to lower the melting temperature. |

| Detergents & Cleaning | Used as a builder in detergents. |

| Chemical Production | Raw material for various chemicals. |

| Paper & Pulp | Utilized in the pulping process. |

| Water Treatment | Adjusts pH levels in water treatment. |

Each of these uses demonstrates the indispensable role of soda ash in not only supporting industrial activities but also enhancing the quality and efficiency of products used daily around the world.

Market Dynamics of Soda Ash

Numerous variables, including as production capacity, industrial demand, and worldwide economic circumstances, impact the soda ash (sodium carbonate) market dynamics. Here’s an overview of key elements that shape the soda ash market:

1. Demand Trends

- Glass Manufacturing: This industry is the largest consumer of soda ash, and its demand correlates strongly with the construction and automotive sectors. The need for glass and, by extension, soda ash, is increasing along with these industries.

- Detergents: The demand for soda ash in detergents remains stable and is influenced by population growth and standards of living. Developing regions showing increases in these areas typically see a rise in soda ash demand.

- Chemical Production: As new applications for sodium carbonate-derived chemicals emerge, this sector also contributes to the overall demand for soda ash.

2. Supply Dynamics

- Major Producers: The biggest producers of soda ash are China, Turkey, and the United States. The production capacity in these countries largely determines the global supply levels.

- Production Costs: The cost of raw materials (limestone and salt) and the energy required for the Solvay process affect the overall supply of soda ash. Efficient mining and processing technologies can mitigate these costs.

3. Geopolitical and Economic Factors

- Trade Policies: Tariffs and trade agreements can affect the global flow of soda ash, influencing prices and availability in different markets.

- Economic Conditions: Global economic downturns or growth influence industrial production and construction, affecting the demand for soda ash.

4. Environmental and Regulatory Impact

- Environmental Regulations: Stricter environmental regulations can influence production methods, potentially increasing costs or forcing the development of greener technologies.

- Sustainability Initiatives: There is a growing trend towards adopting more environmentally friendly production processes, which can shift market dynamics towards more sustainable sources of soda ash.

5. Innovations and Technological Advancements

- Efficiency Improvements: Innovations in production processes that increase yield and reduce waste can alter market dynamics by reducing the cost of production.

- Alternative Applications: Research into new uses for soda ash can open up additional markets, influencing demand and supply dynamics.

6. Market Forecasts

- Future Prospects The market is expected to grow a little during the next several years. This increase is anticipated to be primarily driven by growing markets and expanding uses of environmental technology.

Understanding these dynamics is essential for stakeholders in the soda ash market to navigate the complexities and capitalize on opportunities within this essential industrial commodity.

Environmental and Safety Considerations

Soda ash (sodium carbonate) is widely used across various industries, and while it is generally regarded as safe, its production and usage come with several environmental and safety concerns that need to be managed effectively.

Environmental Considerations

- Ecosystem Disruption:

- Mining Impact: The extraction of trona (natural soda ash) can lead to significant alterations in the landscape and disruption of local ecosystems.

- Water Usage: The mining and Solvay processes both consume large amounts of water, which may strain local water resources.

- Air Emissions:

- CO2 Emissions: The Solvay process releases carbon dioxide, a greenhouse gas, contributing to the carbon footprint of soda ash production.

- Particulate Matter: Mining operations can release dust and other particulates into the air, affecting air quality.

- Waste Management:

- Solid Waste: Both production methods generate solid waste, which must be handled and disposed of responsibly to avoid environmental contamination.

- By-product Handling: The Solvay process produces calcium chloride as a by-product, which must be managed properly to prevent environmental harm.

Safety Considerations

- Chemical Exposure:

- Inhalation Risks: Soda ash dust can irritate the respiratory tract if inhaled, necessitating proper ventilation and respiratory protection in workplaces.

- Skin and Eye Contact: Soda ash is mildly caustic and can cause irritation or burns upon contact with skin or eyes. Protective clothing and eye protection are essential for those handling the chemical.

- Handling and Storage:

- Storage Requirements: Soda ash should be stored in a cool, dry place away from moisture as it can absorb moisture and form lumps.

- Spillage Handling: Spills should be cleaned up promptly to prevent slips and falls, as well as to prevent the substance from entering waterways.

- Transportation:

- Regulatory Compliance: Soda ash must be transported in compliance with local and international regulations to ensure safety and minimize environmental impacts.

Mitigation Strategies

- Technology Improvements: Adopting more efficient mining and processing technologies can help minimize environmental impact and improve the safety of operations.

- Environmental Management Systems: Implementing comprehensive environmental management systems can help manufacturers monitor and reduce the ecological footprint of their operations.

- Employee Training: Regular training for employees on handling, emergency response, and safety protocols is crucial to ensuring a safe working environment.

By addressing these environmental and safety considerations, the soda ash industry can mitigate negative impacts and ensure sustainable operation in alignment with global environmental standards and safety regulations.

New Developments and Opportunities

Environmental concerns and technology developments are driving the soda ash industry’s constant change. Here’s a look at some of the key innovations and prospects that are shaping this sector:

Technological Innovations

- Improved Production Efficiency:

- Advanced Solvay Process: New techniques in the Solvay process are enhancing efficiency, reducing waste, and minimizing energy consumption.

- Enhanced Mining Technologies: Innovations in mining technology allow for more efficient extraction and processing of trona, reducing environmental impact.

- Recycling and Waste Reduction:

- By-product Utilization: Efforts to find commercially viable uses for by-products like calcium chloride from the Solvay process are increasing, helping to minimize waste.

- Closed-loop Systems: Developing closed-loop systems in manufacturing processes to recycle water and chemicals, significantly reducing the environmental footprint.

Environmental Innovations

- Carbon Capture and Storage (CCS):

- Implementing CCS technologies in plants to capture CO2 emissions from the production process, mitigating the impact on climate change.

- Water Conservation Techniques:

- Implementing advanced water management and recycling technologies to reduce the consumption of fresh water in production processes.

Market Expansion

- Emerging Applications:

- Carbon Capture: Soda ash is being explored as a medium for enhancing carbon capture processes.

- Renewable Energy Sectors: Use of soda ash in materials processing for solar panels and other renewable energy technologies.

- Geographical Expansion:

- Exploring new markets, particularly in developing regions where construction and manufacturing are growing, increasing demand for soda ash.

Regulatory and Policy Driven Changes

- Stricter Environmental Regulations:

- Anticipation of tighter global regulations may drive further innovations in soda ash production to meet environmental standards.

- Incentives for Green Manufacturing:

- The possibility of more government incentives for businesses using sustainable practices and green technologies.

Research and Development

- Alternative Raw Materials:

- Research into using alternative, less environmentally damaging raw materials in the soda ash production process.

- Process Optimization:

- Ongoing research into process optimization to further reduce energy use and increase the overall yield of soda ash.

These innovations and prospects highlight the dynamic nature of the soda ash industry as it adapts to changing technological landscapes and regulatory environments, ensuring its sustainability and relevance in the global market.

Conclusion

The soda ash industry, integral to global manufacturing sectors like glass and chemicals, continues to evolve through technological advancements and sustainability efforts. Despite facing environmental and safety challenges, the industry is innovating—from improving production efficiencies to exploring new markets.

With stricter environmental regulations and a shift towards greener practices, soda ash producers are adapting, ensuring their operations are sustainable and ready to meet future demands. As the industry progresses, it remains a vital player in the global economy, poised for further growth and environmental alignment.