In the dynamic world of chemical manufacturing and supply, few compounds are as versatile and widely used as propylene glycol (PG) and polypropylene glycol (PPG). Despite their similar names and overlapping elements in composition, they are fundamentally different in molecular structure, physical properties, applications, and regulatory handling.

Chemical Structure and Classification

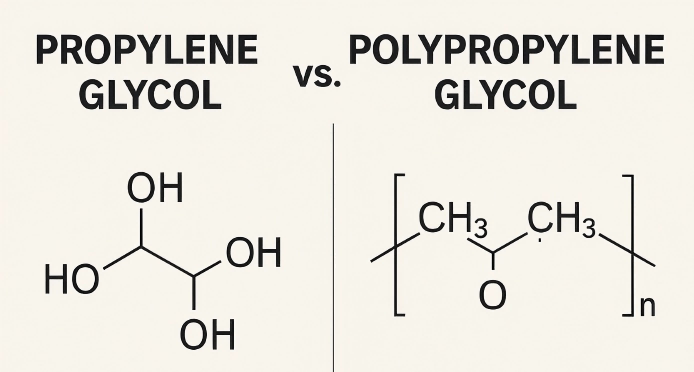

Understanding the structural differences between PG and PPG is crucial to distinguish their behavior in chemical formulations and physical environments.

Propylene Glycol (PG)

- IUPAC Name: Propane-1,2-diol

- Molecular Formula: C₃H₈O₂

- Structure: A small molecule with two hydroxyl (-OH) groups on adjacent carbon atoms.

- Molecular Weight: ~76.09 g/mol

PG is a simple diol, categorized under aliphatic alcohols, and is miscible with water, acetone, and chloroform.

Polypropylene Glycol (PPG)

- IUPAC Name: Poly(oxy(methyl-1,2-ethanediyl))

- General Formula: HO(C₃H₆O)_nH (where n is the number of repeating units)

- Structure: A polymerized form of propylene oxide.

- Molecular Weight: Varies depending on n (ranges from 400 to 4000+ g/mol)

PPG is a polyether diol, resulting from the polymerization of propylene oxide, and is categorized under polyalkylene glycols.

Physical and Chemical Properties

| Property | Propylene Glycol (PG) | Polypropylene Glycol (PPG) |

| Appearance | Colorless, odorless liquid | Viscous liquid to waxy solid (depends on MW) |

| Molecular Weight | 76.09 g/mol | 400–4000+ g/mol (variable) |

| Solubility in Water | Completely miscible | Slightly to moderately soluble |

| Viscosity | Low viscosity | High viscosity (increases with MW) |

| Boiling Point | ~188.2°C | >200°C (varies by MW) |

| Flash Point | ~99°C | >200°C (depending on grade) |

| Vapor Pressure | Low | Very low |

PG is hydrophilic, whereas PPG becomes increasingly hydrophobic as molecular weight increases. This difference affects their usage in aqueous vs non-aqueous formulations.

Production Methods

Propylene Glycol

PG is primarily produced via:

- Propylene oxide hydrolyzes when water is present.

- Two isomers are typically formed: 1,2-propanediol (major) and 1,3-propanediol (minor).

Polypropylene Glycol

PPG is synthesized by:

- Propylene oxide is polymerized by anionic ring-opening.

- Initiators such as water, alcohols, or diols begin the chain, and molecular weight is controlled by the ratio of initiator to monomer.

As a chemical supplier, these production distinctions matter when sourcing, customizing molecular weights, or ensuring purity for downstream applications.

Applications in Industry

Propylene Glycol (PG)

PG is widely used across:

- Pharmaceuticals and Cosmetics: As a solvent, humectant, or carrier in creams, ointments, and oral products.

- Food Industry: Acts as a carrier solvent for flavors, humectant in baked goods, and antifreeze in food processing.

- Tobacco and Vaping Liquids: PG is a primary base for e-liquids in vaping devices.

- Coolants and Antifreeze: Due to its freezing point depression and low toxicity.

- Paints and Coatings: Improves flow and spreadability.

- Hydraulic and Brake Fluids: For lubrication and moisture resistance, PG esters are utilized.

Polypropylene Glycol (PPG)

PPG finds use in:

- Polyurethane Foam Production: A major polyol in flexible and rigid foams.

- Lubricants and Hydraulic Fluids: Due to its high viscosity and thermal stability.

- Cosmetics and Personal Care: Used in shampoos, conditioners, and creams as a thickening and emollient.

- Defoamers and Surfactants: In industrial processes.

- Heat Transfer Fluids: For high-temperature applications.

- Plasticizers and Adhesives: In PVC, rubber, and sealants.

The key difference lies in scale and function—PG is a universal solvent/humectant, while PPG is more functional as a structural or lubricating agent.

Toxicology and Regulatory Status

| Aspect | Propylene Glycol (PG) | Polypropylene Glycol (PPG) |

| FDA Approval | Approved for food, pharma use | Not approved for ingestion |

| Toxicity | Low, Generally Recognized As Safe (GRAS) | Low dermal toxicity, not for oral use |

| Biodegradability | Biodegradable | Biodegradable (depending on MW) |

| VOC Status (US EPA) | Not classified as VOC | Not classified as VOC |

| REACH/ECHA Status | Registered and regulated | Registered and regulated |

PG is FDA-approved for ingestion, while PPG is not intended for food use. As a chemical supplier, product usage restrictions must be clearly communicated based on end-user applications.

Market and Supply Considerations

Cost

- PG is generally cheaper due to high-volume, global demand in food and pharmaceutical sectors.

- PPG pricing is highly dependent on molecular weight, with higher MWs costing significantly more due to processing complexity.

Availability

- PG is readily available globally.

- PPG grades must often be custom-ordered or formulated by polymer chain length, making it more variable in supply.

Packaging

- PG is shipped in drums, IBC totes, or tankers.

- PPG, especially high-MW types, may require heated containers or special handling equipment.

Functional Differences in Formulation

| Property/Use | PG | PPG |

| Hygroscopicity | High | Low to moderate |

| Aqueous Formulation | Excellent compatibility | Limited (depends on MW) |

| Emulsion Stabilizer | Moderate | Excellent in high-MW forms |

| Thickening Ability | Low | High |

| Film Forming | Weak | Strong |

| Thermal Stability | Moderate | High |

| Plasticizing Effect | None | Strong |

When choosing between PG and PPG in a formulation, the decision often comes down to viscosity needs, thermal endurance, and hydrophilic vs hydrophobic compatibility.

Environmental and Safety Handling

Propylene Glycol

- Low volatility and low skin irritation, considered environmentally safe.

- Easily biodegradable.

- Requires basic PPE (gloves, goggles) when handling in bulk.

Polypropylene Glycol

- Non-toxic, but viscous forms can pose handling hazards.

- May form sticky residues, requiring industrial cleaning protocols.

- Biodegradable in low to moderate molecular weights.

Chemical suppliers must provide appropriate MSDS documents, temperature storage limits, and compatibility data to clients, especially in cosmetic or pharmaceutical-grade PG and PPG products.

Use Case Recommendations

| Application Area | Recommended Compound |

| Food & Beverage | Propylene Glycol |

| Vaping / E-liquids | Propylene Glycol |

| Pharmaceuticals | Propylene Glycol |

| Flexible PU Foam | Polypropylene Glycol |

| Lubricants | Polypropylene Glycol |

| High-viscosity emulsions | Polypropylene Glycol |

| Low-freezing coolants | Propylene Glycol |

| Personal Care (emollient) | Polypropylene Glycol (PPG-400 or PPG-1200) |

While propylene glycol (PG) and polypropylene glycol (PPG) may sound similar, their functional profiles and industrial roles diverge significantly. PG is a lightweight, water-miscible solvent and carrier suitable for food and pharma. PPG is a higher molecular weight compound that excels in lubrication, polymer production, and high-performance formulations.

As a chemical supplier, it is essential to match the correct glycol type to its intended application, verify purity and regulatory compliance, and guide clients toward optimal material selection.